Mapping Opportunities for Biomass Energy Development

The processing steps described below are summarized in this crude workflow diagram. It may be helpful to read the processing steps with this workflow as a reference.

Mapping Technically Recoverable Biomass Resources

Clip the ‘theoretical biomass resources’ layer to this procurement area.

Reclassify the theoretical biomass resources layer into masks that represent the spatial distribution of the biomass types that are of interest: e.g., stover (corn); straw (barley, oats, rye, wheat); hardwood residues; and softwood residues. These masks will be used to extract yield for various biomass types. Distinguishing these different biomass types is important because some biomass conversion technologies are better suited for specific biomass types, and biomass conversion technologies are often designed relative to the source of feedstock (stover vs. straw vs. wood).

Estimate annual yield for each source of biomass on a per pixel basis. In our case, we used the following approach (summarized ici):

Agricultural residues: agricultural census statistics are used to generate an 8-year average for the total yield of a given crop over its enumeration area (e.g., at the County level in Ontario). To this average yield we apply a residue production factor, which estimates the amount of residue produced for a given yield of crop, and then we apply a 30% conversion factor, which means we are assuming that we will leave 70% of the residue on the field to maintain soil quality. The final value will be in tons/acre and needs to be converted into a per-pixel value. See ici for an example of how these conversions all break down using agricultural statistics from the province of Ontario as the baseline. Reclassify the land-cover map to apply this per-pixel value to its respective land-cover type.

- Annual harvest rate: 2.2% of total area

- Residue from selective harvest: 2 oven dry tonnes per hectare

- Residue from shelterwood harvest: 10.8 oven dry tonnes per hectare

- Residue from clear cut harvest: 16.8 oven dry tonnes per hectare

Information about the harvest regime that is typically applied in a given area can be found in forest resource inventories, described in the ‘theoretical resources’ section above. Knowing the harvest regime applied, mapped across relevant land-cover categories, can generate a total volume from which we estimate only 2.2 % as the technically available volume in any given year. See also this study for further guidance on how forest resources might be mapped in your area.

It is now possible to compute total available tons of biomass residue within the procurement area, broken out by biomass type using land-cover masks.

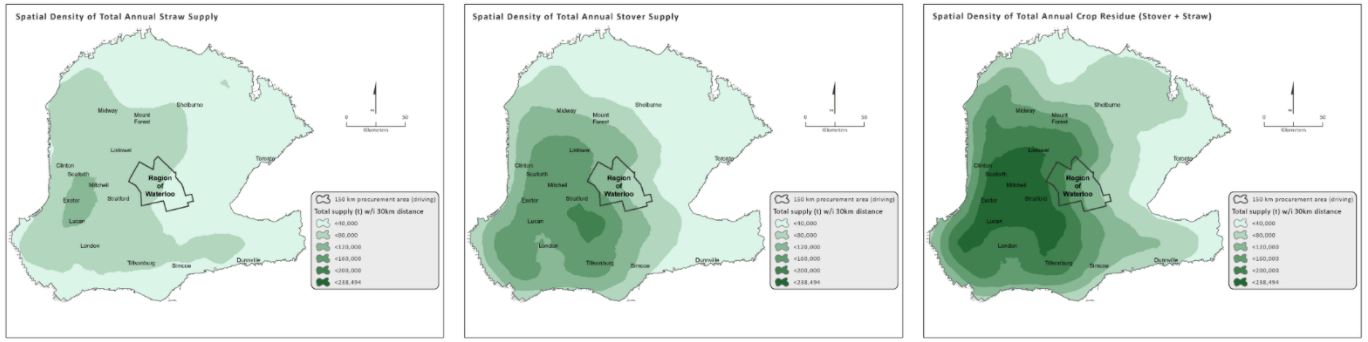

Another important characteristic is spatial density: i.e., identifying where biomass resources are available in highest spatial concentration (see Figure below for an example).

Figure 1: Example biomass density maps.

The workflow to produce these maps is as follows:

- For each of the final spatial layers (e.g. spatial distribution of solar) apply the Spatial Analyst FOCUL STATISTICS tool to calculate the focal sum for a 1,000 cell circular radius (approximately 30km radius).

- This will yield a density map for each resource. You can also apply RASTER CALCULATOR to calculate the total crop residue layer as the sum of the three individual 30 km layers.

- Adjust the legend classification as necessary and copy to all layers. For comparison purposes, we recommend that all four layers follow the same classification scheme.

Mapping Legally Accessible Biomass Resources

Currently, there are not any regulations that restrict access to biomass residues. Our analysis does, however, consider non-regulated sustainability concerns in two ways:

- We do not assume conversion of land into biomass energy production, but rather assume that biomass would come from the existing agricultural land base.

- We limit the recovery of biomass residues to only 30% of what would be theoretically available. In this way, we ensure that at least 70% of the residue base is left on the field to maintain soil nutrient levels.

Mapping Relative Spatial Costs of Biomass Resources

With total available biomass at each distance (supply-distance) computed for stover, straw, and woody residues respectively, it is now possible to calculate supply-cost curves for each of these resources. This calculation uses an excel spreadsheet, made available ici, which includes all cost assumptions as well as the ability to change those assumptions. This will help to provide an understanding of the feedstock costs delivered to the factory gate. If you wish to examine a specific site or bioenergy technology in more detail, including costs related to technology and finance, there are a few tools that may be applied, including RETScreen from Natural Resources Canada and System Advisory Model (SAM) from the National Renewable Energy Laboratory (U.S.)